Barcotec moves OMV with the help of RFID system

Large industrial plants such as those of the OMV refinery require regular maintenance. With the help of an automatic RFID tagging system from Barcotec, the maintenance of the large parts of the OMV plants in Vienna-Schwechat could be significantly simplified.

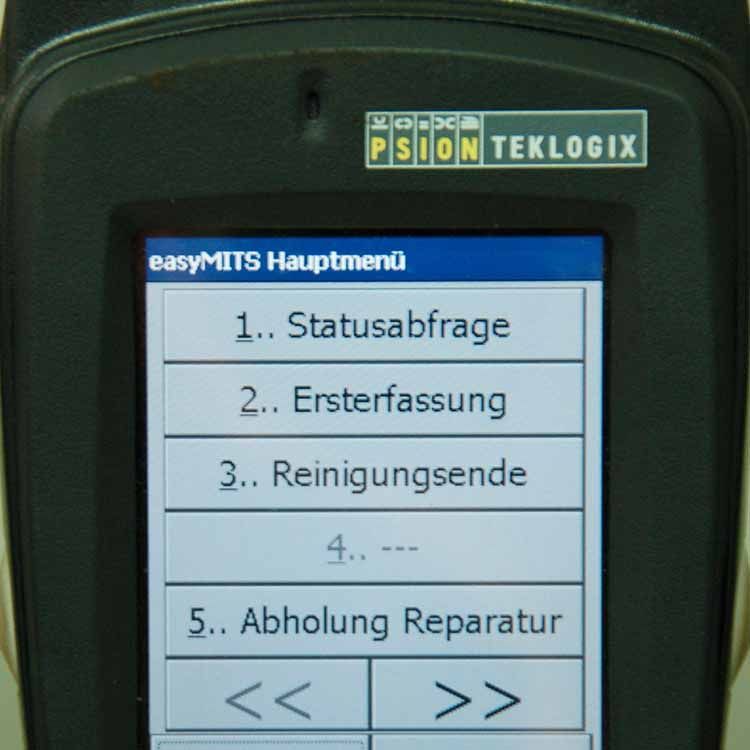

For this purpose, the parts to be maintained are provided with special RFID tags suitable for industrial use and mobile RFID readers are used, which send the data directly to the central SAP system via the "easyMITS" software.

Lyes and high pressure - only possible with RFIDThe Schwechat refinery is one of the largest and most modern inland refineries in Europe. Distillation and refining processes turn crude oil and semi-finished products into high-quality petroleum products and petrochemical base materials. Every year, the high-tech plants in Schwechat process 9.3 million tonnes of crude oil - that is about half of all petroleum-based products used in Austria. The plant components are subjected to regular maintenance, and the Austrian TÜV then checks compliance with the official requirements.

In the course of the maintenance work, the plants are brought to a standstill, dismantled into individual parts and checked. The components are then cleaned with lye and high pressure at the so-called "washing station".

In order to be able to clearly identify all dismantled parts before and after the washing process, they are provided with extremely robust RFID tags; the capture of the tags is carried out with mobile and particularly industry-suitable data capture devices.

The project team tested a wide variety of materials for labelling tags for their durability and readability after the washing process.

"The tags (RFID data carriers) have to withstand heavy loads and must not be destroyed during the washing process," explains Alexander Rainsberger, Managing Director of Barcotec. "After intensive tests, it was clear to us that RFID is the best labelling medium for such loads. We developed special cylindrical tags that safely survive the washing process."

Flexibility and speed

A major advantage of the RFID system is the optimisation of storage space and thus the manageability of the intermediate storage at the washing station. The identification system provides information on which parts have priority and are to be cleaned next, for example because they have to be reinstalled in the system first. This avoids delays and ensures that the required planning times are adhered to.

The mobile data capture devices can not only read RFID tags, but also barcodes. As soon as a finished cleaned part leaves the washing station, a delivery note with information about the collector as well as the destination is created by means of a simple scan of a barcode.

The great advantage of using the "easyMITS" software is that the scanned data is automatically transmitted from the mobile device to the ERP system. This means that the data is always available live in a central location and it is always easy to see which parts are currently where and in which status.

The innovative system makes it possible to create a history for each piece of equipment and thus ensure complete traceability.

A sophisticated RFID complete package

Barcotec provided OMV with a full-service package: from RFID tag development to the mobile data collection device to the middleware "easyMITS", everything came from a single source.