8 hours time saving thanks to Barcotec system

Steinbacher Dämmstoffe, one of Austria's leading insulation manufacturers, handles and accelerates its processes with a data collection solution from Barcotec. With the previous approach, the stock level could not be retrieved up to date and the frequency of errors was high. Data capture devices and easyMITS from Barcotec helped to optimise this.

"Before the introduction of the mobile data capture solution, it took a production employee about 45 minutes to make 50 goods receipt entries; now the same work can be done in less than 5 minutes." the Steinbacher ERP manager is pleased.

Before the introduction of easyMITS, all goods receipts from production were posted manually in the ERP system. These bookings were entered collectively with a time delay (1 time per day). This meant that an up-to-date stock level in the ERP system could not really be guaranteed. Furthermore, errors (wrong article number or quantity) occurred again and again when entering the manual bookings.

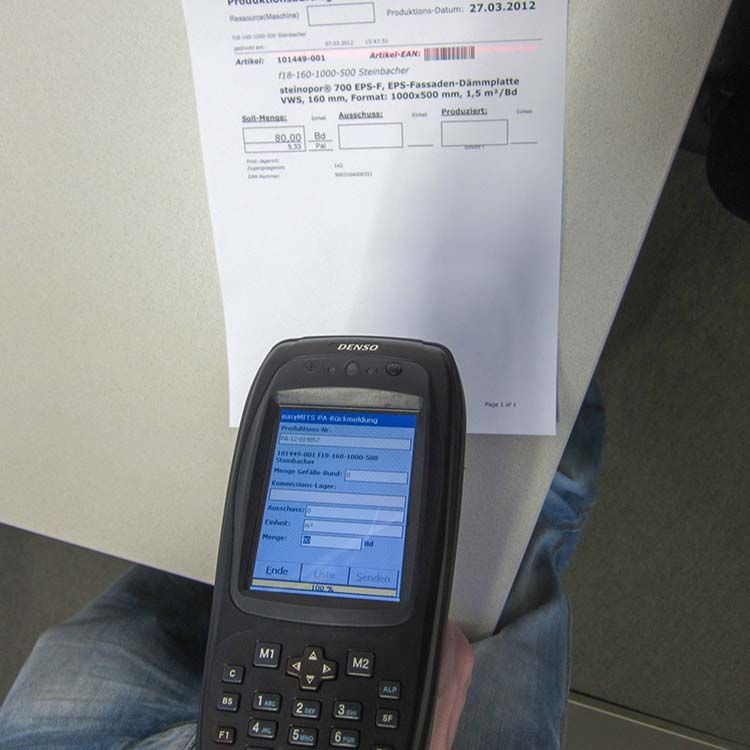

Steinbacher Dämmstoffe therefore now uses data capture devices from the manufacturer Denso in combination with Barcotec's connectivity software "easyMITS".

The advantages were clear for the company: "Barcotec is the contact for hardware and software, so we got the solution from a single source. Furthermore, the geographical proximity and the excellent references were important decision criteria for us. We were impressed by "easyMITS" because of its simple adaptability," the ERP manager continues.

The "easyMITS" configurator helps to develop and adapt the required processes individually and easily. Via ODBC, various external data sources, such as the SQL server database of the ERP system, can be accessed within the processes and used for queries and test routines. The system has worked smoothly since the beginning. The primary goals of being able to call up an up-to-date stock level and reducing the frequency of errors have been fully achieved. Gosch concludes: "We are very satisfied!